Objectives and status

Development of processes for wet chemical lift-off and substrate reuse

-

Wet etching experiments performed and developed further. Optimized etch rate achieved by structuring of cap layer followed by selective chemical etching. (Figure 3 top picture)

-

Large area lift-off was achieved. Further development will focus on stabilization of the lifted-off III-V film in order to avoid breaking thin film during further processing. (Figure 3 centre)

-

Etch stop layers were efficiently removed by selective etching. Bottom pictures show AFM pictures for new wafer and substrate after lift-off and cleaning. Surface roughness of used substrate shows suitability for regrowth.

Development of processes for laser lift-off and substrate reuse

-

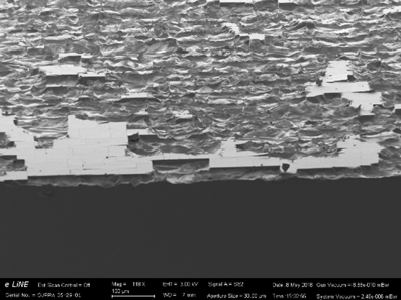

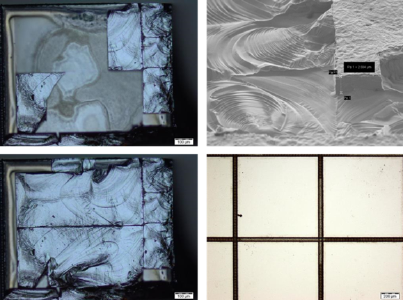

Laser lift-off process developed further. Large area lift-off was achieved. Left pictures (Figure 4 top and bottom) show top layer before and after lift-off. SEM measurements show that lift-off actually happens at the desired depth (Figure 4 top right).

-

Efforts on process development results in minimization of structural damage to layers adjacent to sacrificial layer.

-

Further development will focus on pre-structuring of the layer to be lifted-off (Figure 4 bottom right). In addition, emphasis will be set on the stabilization of lifted-off. III-V layers in order to make them suitable for further processing.