Objectives and status

Development of industrially scalable low cost processes for the front contact grid of the tandem solar cells, with Total series resistance of electrodes (contact resistance and bulk-resistance) < 1 Ohm cm² and less than 2% of the front side shaded area by electrodes.

-

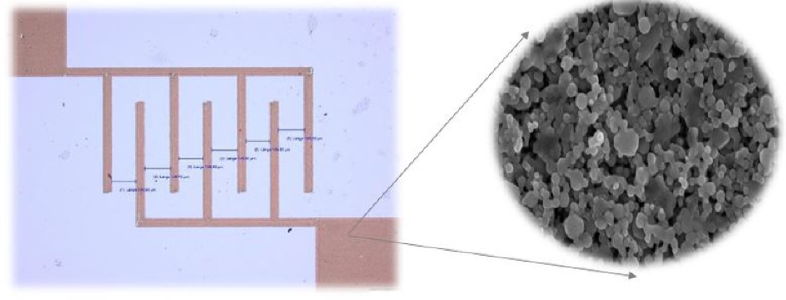

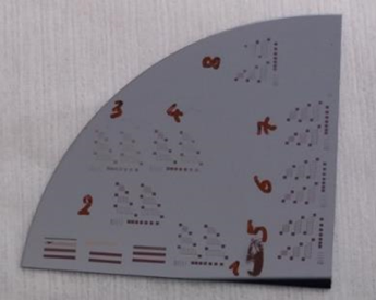

Fine printed electrodes with adjustable size and thickness were developed further (top).

-

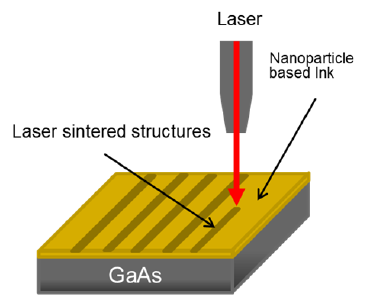

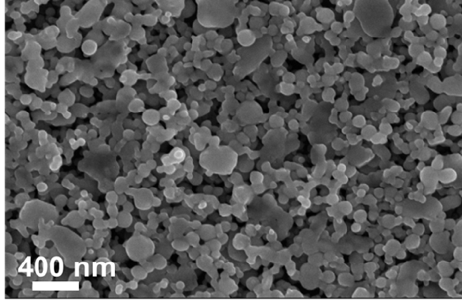

Laser sintering was chosen for further steps as a sintering method with high effectiveness and low costs as well as low environmental effects (bottom).

-

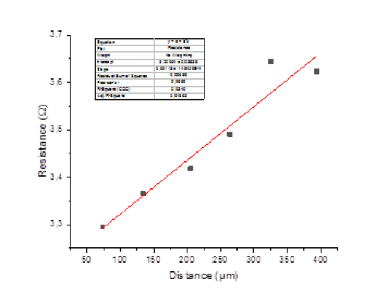

Further investigations with TLM measurement, SEM, XPS, UPS and AFM revealed significant improvements in the quality of sintered electrode within the last 6 months.

Objectives and status

-

The sintering process was optimized in order to achieve a sintered electrode with good adhesion and desired reproducible electrical behaviour with low contact resistance (top). The thickness of this electrode was adjusted to improve the microscopic integrity of the thin electrode (bottom).

-

Further development will focus on consideration of an intermediate layer for electrode contact and pattering the CAP layer by employing protective layer.

-

Electroplating will be developed and utilized for the growth of final front-contact electrodes.